|

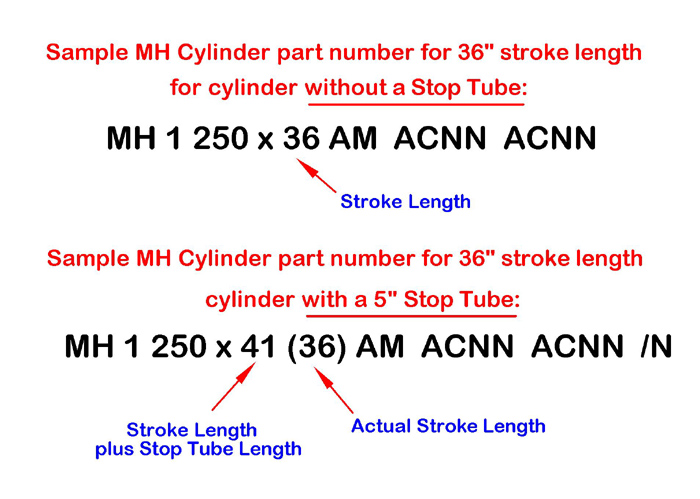

The use of a “Stop Tube” placed in either an air or hydraulic cylinder is an effective means of reducing the side load imposed upon the cylinder rod cartridge in long stroke horizontal applications. The Stop Tube basically prevents the piston within the cylinder from bottoming out against the head end cover, thereby, increasing the support of the piston rod. Proper utilization of Stop Tubes will significantly reduce rod cartridge failure in this type of long stroke application. Generally speaking, one should consider the use of incorporating the Stop Tube feature in cylinder stroke lengths in excess of 36”, however, the cylinder mount and load weight will be two of many other factors used in determining if a Stop Tube is required for your application. The cylinder mounting style and other data applicable to the application at hand are important factors to know in making the determination for the correct length of the Stop Tube. Please note that when a Stop Tube is used; the cylinder length will grow, beyond the standard NFPA length, by the same extent as the length of the Stop Tube. See the below example for Stop Tube part number description. The Example below shows a Stop Tube Part Number Description. ( NOTE - when entering a Stop Tube into our configurator, please enter the ACTUAL stroke required, then enter required stop tube/ spool length in the top section )

Some additional issues to consider in making the determination for the correct Stop Tube length are as follows, we recommend that you discuss all of these and other relative issues with our engineering staff if you are unfamiliar with the use of cylinder Stop Tube applications:

Peninsular’s design for Stop Tube applications incorporates the use of improved engineering features over many conventional Stop Tube designs which are commonly found within industry today. Peninsular’s design for Stop Tube applications incorporates the use of improved engineering features over many conventional Stop Tube designs which are commonly found within industry today. Illustration #1 below: Shows Peninsular's Improved "Stop Spool” Design Illustration #2 below: Shows the Conventional "Stop Tube” Design

Advantages for Peninsular's Stop Spool:

By selecting the Stop Tube feature a /N will become present in the cylinder part number after you have submitted the cylinder for configuration, and both the actual stroke and the overall total stroke length will become present in the cylinder part number.

Toll Free: 800-526-7968 Phone: (586)

775-7211 Fax: (586) 775-4545 |