Do You Really Want to Unscrew That Cartridge Valve?

Unscrewing a valve or fitting from a cylinder under load may pose unforeseen consequences.

I’ve met hundreds of knowledgeable people in my many years working in the fluid power community. Almost all have been people of excellent character, and some are passionate about what they do. No one is more passionate than Rory McLaren, director of the Fluid Power Safety Institute. Rory’s passion is safety in fluid power.

Like most seasoned professionals who are passionate about what they do, Rory is full of interesting stories we can learn from. Rory shared with me a situation he encountered while conducting a hydraulic safety workshop for a of large equipment rental company. A student told him that an aerial lift platform had tipped over. After the machine was righted, the engine could not be started. This was because oil flowed from the engine’s crankcase into the cylinders when the machine laid on its side.

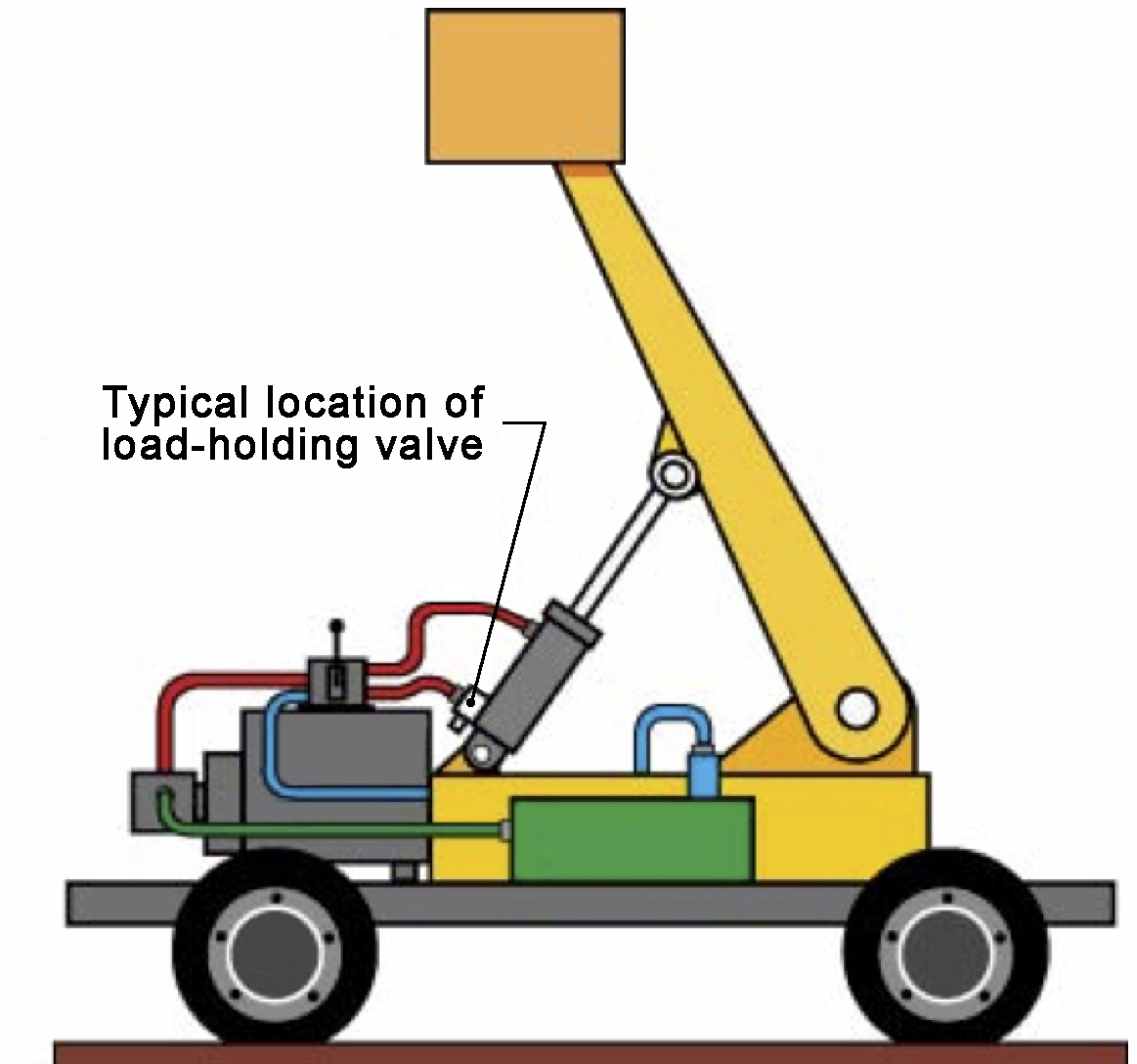

Lift cylinders have a counterbalance or pilot-operated check valve as a load-holding device. The valve prevents the load from dropping if a hydraulic line is ruptured or breaks loose. The lift cylinder can only retract if the load-holding valve is open, which requires pilot pressure. With no pilot pressure, the valve blocks fluid from flowing from the cap end of the lift cylinder to tank.

The maintenance technician discussed the problem with his supervisor, who wisely advised him to consult the manufacturer. A rep from the aerial lift manufacturer advised unscrewing a cartridge (load-holding) valve from the base (cap end) of a boom lift cylinder to relieve pressure from the cylinder. Unfortunately, this advice is common. More specifically, the manufacturer’s technical rep told to mechanic to “carefully” unscrew the safety valve out until it was free of its O-ring seal. Doing so would let fluid leak out past the threads and allow the boom to lower very slowly.

The only way to lower the boom is to remove the oil trapped in the cylinder between the piston and the load-holding valve. However, loosening or removing the valve is not the only way of dissipating the unpredictable amount of stored energy from the cylinder. In fact, it is quite dangerous because the cylinder has become, functionally, a weight loaded accumulator.

The situation presents serious safety hazards for several reasons:

- The pressure generated by the total weight of the boom, piston rod, and the surface area of the piston, can be extremely high—enough to easily penetrate the skin or blow out an eye.

- Flow and the resultant velocity of the fluid exiting through the cylinder port are unpredictable and can be extremely high.

- If inadvertently removed, the cartridge valve becomes an aimless projectile, which could easily penetrate safety glasses or cause serious injury.

- If hot, and depending on its volume, the oil could strike at any distance and cause serious burns.

- Atomized oil sprayed from the cylinder port could cause an inferno if it contacts a hot exhaust manifold, an exposed electrical panel, an electric motor, or heating element.

I don’t know the final outcome of the aerial lift at the equipment rental company, but Rory described a similar situation that occurred at a mine in Globe, Ariz. A mechanic, following the advice of a factory expert, was unscrewing a load-holding valve out of its housing to lower the boom on a basket lift with a disabled engine. The valve’s threads, acting as an adjustable orifice, restricted the leakage to a few drops per minute. Naturally, the mechanic became impatient, so he decided to “give it another turn,” as he put it.

With only one or two threads left in the valve body, the static pressure of the fluid, and its resultant force against the cartridge valve, sheared the threads, propelling the valve out unexpectedly. The ensuing jet of oil blew both the mechanic’s safety glasses and hard hat off and sent him reeling backwards to the ground. His colleagues scattered in all directions. Needless to say, the basket’s mast came crashing down, causing severe mechanical damage. Although someone could’ve been killed, fortunately, no one was even injured.

So how do you safely retract a cylinder holding up a load when there is no pilot pressure? One way is to use a hand pump or small auxiliary pump to generate pilot pressure, and then use the directional valve to retract the cylinder. An easier method is to use a hydraulic microbleed valve to safely relieve pressure from a component or circuit.

By: Alan Hitchcox

After serving as a vehicle mechanic in the US Army, Alan attended college full time to earn a Bachelor of Science while also working full time for a power transmission and fluid power distributor. He then became a technical editor and wrote or edited hundreds of technical articles for 38 years, with the last 32 on Hydraulics & Pneumatics magazine before becoming semi-retired in 2020.

Leave a Reply

You must be logged in to post a comment.